A Responsible Care logo-holding company since 2016, Gulbrandsen Technologies, Inc. (GTI) has received an additional recognition from the Indian Chemical Council (ICC): the Epsilon Carbon Certificate of Merit for Best Compliant Company under the Council’s Pollution Prevention Code.

A Responsible Care logo-holding company since 2016, Gulbrandsen Technologies, Inc. (GTI) has received an additional recognition from the Indian Chemical Council (ICC): the Epsilon Carbon Certificate of Merit for Best Compliant Company under the Council’s Pollution Prevention Code.

Established in 1938, the ICC is dedicated to the ethical and sustainable growth of the Indian Chemicals Industry – as well as to increasing India’s global exports of chemicals and chemical products.

Its Responsible Care program requires participating companies, such as GTI, to sign a voluntary commitment to the program’s guiding principles and to undergo a gap assessment to identify improvement measures required for compliance. To maintain status as a Responsible Care logo-holder, GTI must resubmit its KPI/GPS/PSE information annually.

The Pollution Prevention Code is one of six codes of management practice that participant companies must uphold to qualify for Responsible Care logo status every year. In the most recent recertification cycle, GTI was judged to be the most compliant participant company in its demonstration of this code.

“We’re very proud of our status as a Responsible Care logo-holding company”, said Vikram Singhal, GTI President. According to Vikram, GTI works towards reducing the environmental footprint of its own operations, while making quality products that help its clients meet their ESG (Environmental, Social, Governance) goals.

Through communication and training, GTI also encourages employees, vendors, customers, visitors and the communities in which it operates to follow safe and environmentally-friendly practices.

“At Gulbrandsen Technologies, we are passionate about science and the power of innovative chemistry to improve health and wellness across the globe. At the same time, we’re constantly working to balance both the environmental and business needs of our customers.

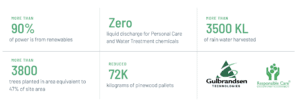

For example, the company has undertaken several initiatives in recent years to cut water and fuel consumption, while increasing the use of renewable energy within its operations and reducing waste, otherwise destined for landfill.”

Check out the results!